|

|

|

Established 50 years ago, as one of Australia’s leading small engine machining workshops, Serco is still at the heart of performance engineering to this day. |

|

|

|

|

|

Workshop Services

|

Newen CNC Machine Seat CuttingThe Newen Contour BB is the most advanced machine of its type on the market. It machines the smallest size valve seats with maximum precision and has single point cutter to cut even the hardest seats. Fixed turning means no chatter on the hardest of cut seats. The Newen Contour BB is used by the leaders of the racing industry, and OEM Manufacturers. |

Complete Cylinder Head Reconditioning

|

|

|

Crankshaft RebuildingSerco can rebuild crankshafts for many applications, including, ATV, dirt bikes, side by sides, both 2-cycle and 4-cycle, single cylinder. Our experience and precision in crankshaft rebuilding is unmatched in the industry at any price, and we can deliver a rebuilt product that will meet and exceed any O.E.M. crank. |

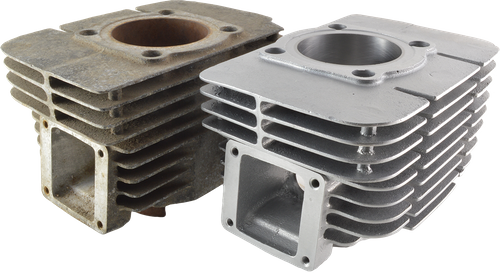

Cylinder Resleeving, Boring, Honing & PortingSerco is able to bore, hone, or resleeve any cylinder. When boring or resleeving a cylinder the cylinder needs to be completely torn down. The typical time to resleeve a cylinder is between 2 - 3 hours. Please note: It is sometimes necessary for the cylinder to be welded. Welding the cylinder is an additional charge. |

|

Also Available

|

Custom Repair WorkWe offer a complete reconditioning and restoration service for vintage to modern cylinder heads. As in the case of this Jawa 250 Speedway Cylinder Head, we can also upgrade to larger valves, redesign the combustion chamber ect. Contact us today to book in your customer repair work. |

Wet BlastingThe Wet Blast process is a unique blast finishing technique that can be used on motorcycle, automotive and marine parts and is best suited for ferrous and non-ferrous metals. The wet blast process utilises abrasive media, water and compressed air to induce a scrubbing action on the surface of the material being processed. Wet Blasting does not cause surface damage to components, therefore threads, seal surfaces and other sensitive areas do not have to be protected before wet blasting. |

|

Other Services

Custom Porting |

Full Engine Rebuild |

Custom Repair Work |

Contact Us07 3362 6600sales@serco.com.au108-114 Steel Street, Capalaba, QLD 4157

Trading Hours:

|